Industrial & Manufacturing

The adoption of advanced manufacturing systems and Industry 4.0 technologies depend on more real-time fiber optic sensor and measurement data to drive efficiency and performance gains in industrial processes.

Overview

Luna's terahertz technology and fiber optic sensing systems equip manufacturers and engineers with the tools needed to optimize processes. Real-time and reliable, T-Gauge terahertz sensing systems monitor difficult parameters such as multilayer thickness and density with speed and accuracy. Luna's ODiSI delivers high-definition temperature mapping capability using fiber optic sensing, resulting in more data and information for process characterization and optimization.

- Industrial process control

- Non-destructive testing (NDT)

- Imaging through material

- Multilayer thickness measurement

- Spectroscopic measurements

- Thermal mapping

- Distributed temperature sensing

- Quality controlling

Explore Key Solutions below for examples of how Luna systems are helping manufacturers improve their processes and products.

Featured Products

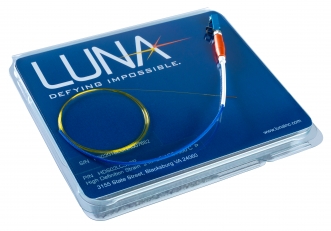

High-Definition Distributed Fiber Optic Sensing

ODiSI Interrogators

High-Definition Sensors