Process Control and Non-Destructive Testing

Non-Destructive Testing with Terahertz Technology

Handheld terahertz sensors can measure and scan specialty coatings and multilayer structures to check thickness consistency and locate subsurface detects. For example, terahertz systems can be used to inspect the high-performance coatings used on military aircraft, verifying coating thickness with submicron accuracy. Terahertz measurements are also useful for aiding the in-service inspections and repairs of external coating.

| Industry | Application Area |

|---|---|

| Aerospace |

|

| Marine |

|

| Building Products |

|

| Petrochemical |

|

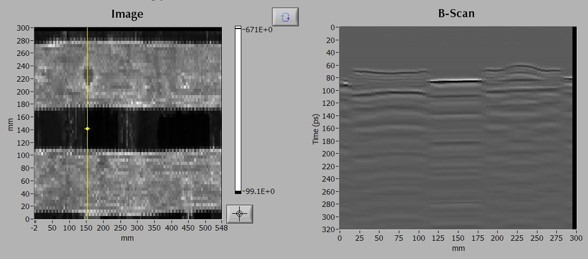

Terahertz measurement systems are also able to verify the structure of multilayer materials with a single sensor. A terahertz system outfitted with a line scanner gauge can produce B-scan images of defects, subsurface structures or provide precise offset and separation measurements.

Featured Products

Terahertz Gauging and Imaging

TeraMetrix is Luna’s product line for terahertz gauging and imaging, using pulsed terahertz waves to provide precise measurement of single and multi-layer thickness, density, basis weight and caliper thickness.