Structural Health Monitoring for Energy Systems

Structural Health Monitoring in Energy Applications

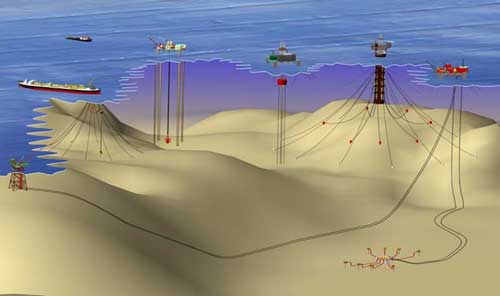

High-value assets that are critical to the acquisition, processing and distribution of energy throughout the world are being monitored and better maintained with fiber optic sensing systems. Condition monitoring and structural health monitoring (SHM) of wind turbines, hydroelectric plants, oil and gas rigs, risers and other systems provide owners and operators with real-time data and information on the operational health of the critical components.

SHM Systems Based on Fiber Optic Sensing

Fiber optic sensors form the backbone of condition monitoring systems, with several measurement benefits for energy applications, including immunity to EMI and lightning, corrosion resistance, and the ability to easily distribute large numbers of sensors on very large structures.

For example, wind turbine systems can be monitored with a variety of sensors to provide crucial operational data on its performance and health. Optical strain gauges, accelerometers, and temperature sensors provide accurate and reliable data for:

- Blade dynamic loading

- Blade damage and delamination

- Tower bending, fatigue and vibration

- Bearing and gearbox temperature and vibration

- Real-time dynamic sensing for active pitch control

Similarly, fiber optic sensors can tackle the most demanding applications such as monitoring subsea flexible risers used on offshore platforms. With capacity of 100s to 1000s of sensors and the performance to capture both static and dynamic measurements, the HYPERION fiber optic system can be used to provide real-time damage detection and basic riser shape data for the condition monitoring of these critical components.

Featured Products

High-Speed Multipoint Fiber Optic Sensing

FBG and FP Sensors