Benefits of Fiber Optic Sensing Versus Electrical Gages

Over the past few decades, Luna has leveraged fiber optic sensing technologies in applications spanning multiple industries. From structural health monitoring of bridges, wind turbines, and aircraft to high-definition strain and temperature mapping of composite materials, batteries, and prototype parts – fiber optic sensing (FOS) has been proven to provide accurate, reliable measurements in harsh and demanding environments. While electrical sensors have been the industry standard for over 80 years, they have limitations that make them a sub-optimal choice for many applications in which fiber optic sensors excel.

Why do customers choose FOS over electrical gages?

- Quick and easy to install, providing more data in less time while reducing installation costs.

- Long-term accuracy and reliability with zero drift, including in high cycle, high fatigue applications – whereas electrical gages require frequent recalibration.

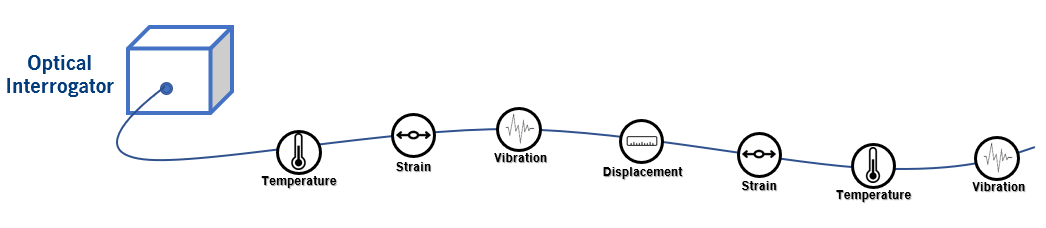

Multiple sensing points along a single fiber, reducing the total number of cables required for installation. On a single fiber, Luna’s HYPERION can simultaneously measure strain, temperature, acceleration, displacement, etc.

- Electrically passive and environmentally stable. Fiber optic sensors are immune to electromagnetic interference (EMI), unaffected by high voltages, and won’t corrode. They can also be used in explosive environments where other sensors are prohibited.

- High sensor capacity on single data acquisition system. 1000’s of sensors can be connected to a single DAQ, making it easier to correlate data between sensors without the need for synchronizing the timestamps of multiple systems.

- Ultra-High spatial resolution. Luna’s ODiSI can measure strain or temperature with a gage pitch (spacing of adjacent gage center points) of 0.65 mm, providing more data for process control optimization and allowing insights into critical points and unexpected features on manufactured parts.

- Long range sensing. Sensors can be located multiple kilometers away from the instrument and no power is required at the location of the sensors.

The measurement possibilities with fiber are endless. While electrical sensors are still useful for many applications, there is no doubt that the future will be enabled with fiber.

To learn more about the HYPERION, ODiSI, or other Luna Innovations fiber optic sensing technologies, please contact us at [email protected].