Luna Launches Innovative Automotive Pressure Testing Method

Luna recently launched an innovative new pressure sensor and system to measure the dynamic pressure distribution across the surface of a moving vehicle using fiber optics and Luna interrogators to capture the data.

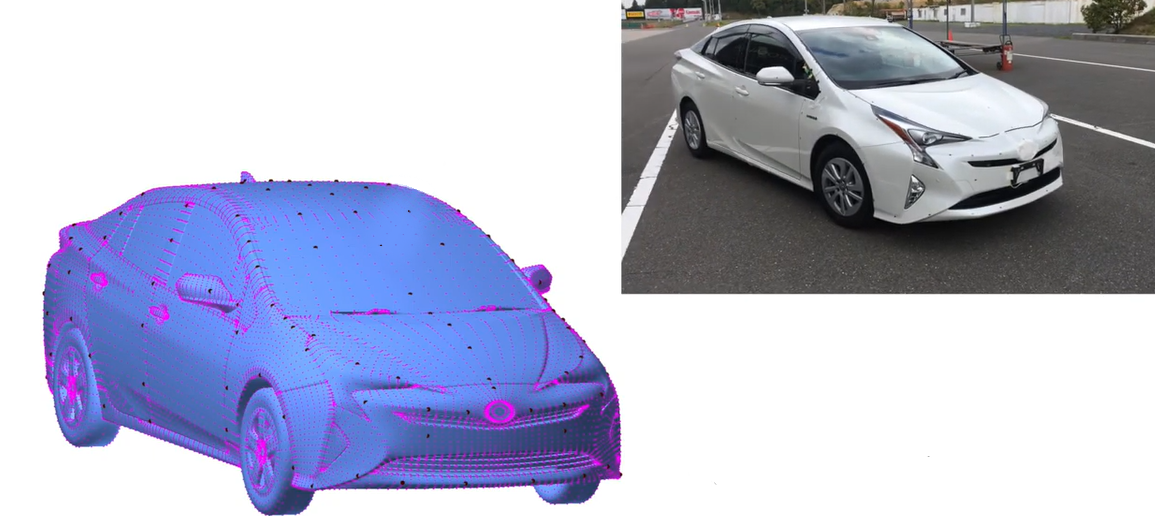

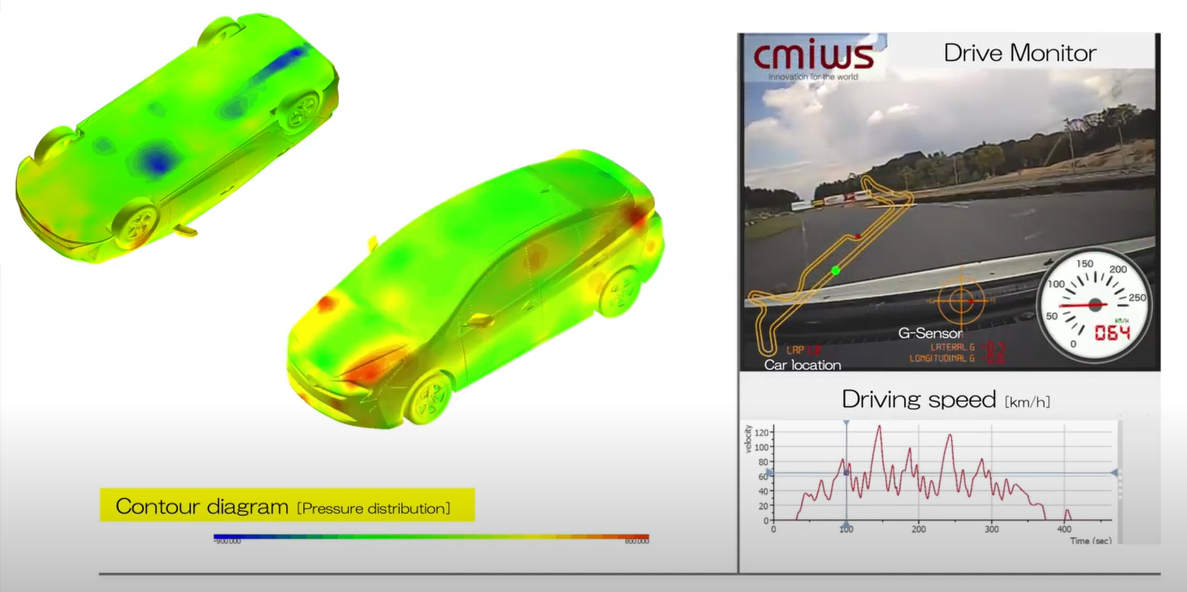

In the pilot program with partner CMIWS in Japan, 191 Fiber Bragg Grating optical pressure sensors were installed on the surface of the test vehicle, and the test measurements were collected with a Luna HYPERION si255 data acquisition interrogator. In this test, the data sampling speed was 1,000Hz, although higher sampling speeds of 5,000Hz are also available. Turbulent flow and separating flow were expected.

Data from the pressure sensors were synchronized with the driving data logger which acquires speed, car location, and acceleration from the global positioning system (GPS) and controller area network (CAN), and digitized into a contour map.

Prior to the development of this method with these tools, it has been difficult to measure the pressure distribution of a moving vehicle, since it would have been necessary to make multiple holes in the body of the car to accommodate tubing or for embedding pressure sensors. In addition, there were limits to the number of sensors you could have used with this older method, as well as challenges with easily relocating sensors.

Installation of the FBG sensors for the test was simple with the use of double-sided adhesive tape – no holes or tubing were required. The pressure sensor has a thin profile, with high pressure sensitivity and high resolution, and is not affected by electromagnetic noise like traditional electric sensors are. FBG sensors measure the wavelength shifts by fiber stretching and converting it into a physical quantity, measuring not only pressure, but also temperature, strain, displacement and acceleration.

The development of this technology is a breakthrough for automotive manufacturers, because unsteady pressure fluctuations can be measured -- real aerodynamics -- when accelerating, braking, turning, overtaking, etc.

For information on CWMIS’ pressure distribution testing program, see the CMIWS video here or contact us for more information on the Luna HYPERION si255 optical interrogator or Luna's os9100 optical pressure sensor.