Thickness Monitoring

For many manufactured products, the ability to accurately measure multilayer thickness is critical to ensure consistent quality, minimize defects and reduce material usage. Terahertz technology provides a measurement solution that has many benefits, including

- Non-contact measurements

- Works with both opaque and translucent materials

- Multilayer thickness measurement

- High resolution and accuracy

Terahertz Technology

Terahertz radiation is part of the electromagnetic spectrum lying between microwaves and the far-IR, with frequencies ranging from 0.1 – 10 THz and wavelengths from 3 mm to 0.03 mm. Terahertz radiation can be used to gauge and image through materials yielding high temporal resolution (down to a micron) and can resolve both time and amplitude information. This type of sensing has high signal-to-noise ratio, can produce images and can observe internal structures.

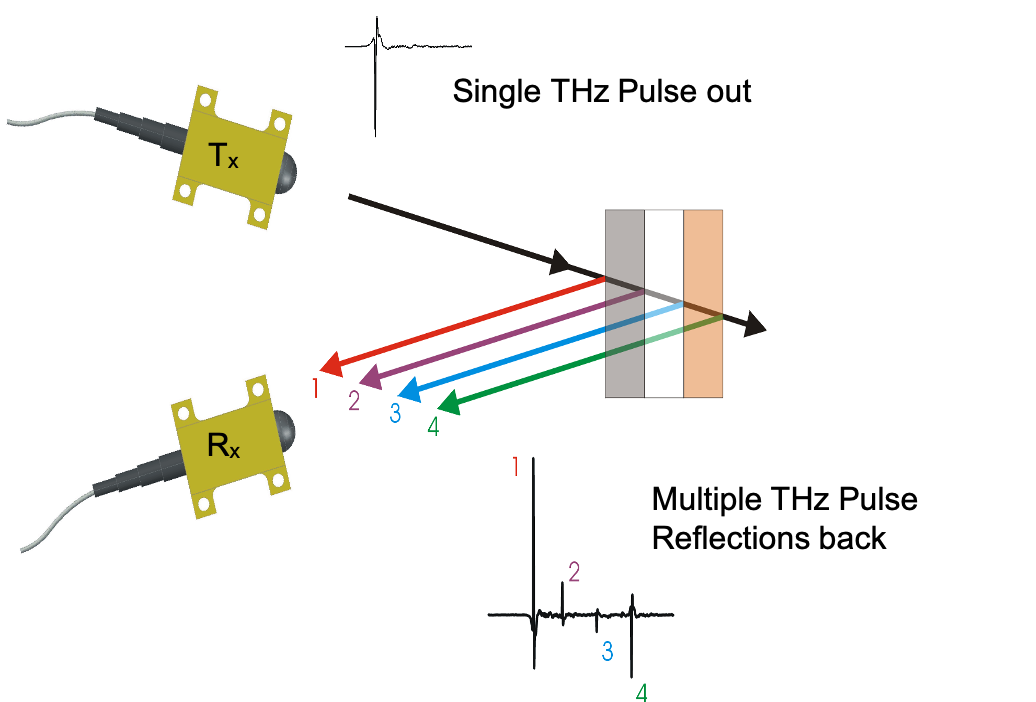

Multilayer Thickness Measurement

Unlike traditional thickness measurement techniques, terahertz sensors can easily measure multiple layers with high precision. For example, with thin-wall multilayer packaging materials that incorporate an EVOH barrier layer, traditional infrared thickness gauges cannot determine the location of the EVOH layer, and the total amount of material, and only on materials that are transparent enough to the infrared radiation. A single terahertz sensor can distinguish and measure all three of the co-extruded layers even when opaque.

Because terahertz sensor measurements are non-contact and real-time, high-precision thickness measurements can be used as feedback to improve and optimized manufacturing processes.

Featured Products