The Luna Quarterly

Application Spotlight: Using Terahertz Systems to Measure Critical Parameters in Medical Tubing

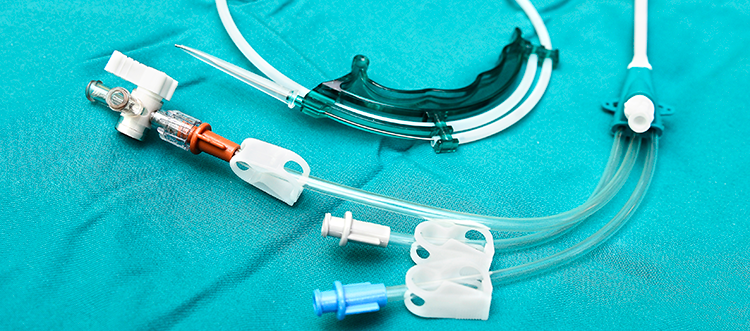

Medical tubing and catheters require precise uniform wall thickness to provide predictable performance in life-critical applications. As the demand for more complex, precisely controlled medical tubing grows, it is critical to have monitoring methods that can supply manufacturers with the comprehensive range of product information required to validate their products.

Most high-performance medical tubing products are produced by extrusion processes. During the extrusion process monitoring of the critical product parameters – single and multilayer wall thickness, concentricity, outside diameter (OD) and inside diameter (ID) – is currently performed by a combination of laser gauges for dimensions and ultrasound for wall thickness measurements.

The closer the measurements are made to the extruder, the more responsive the whole system can operate and more quickly correct for variations in product. However, ultrasound measurements require contact with the sample through a couplant and ultrasonic methods can only measure the near side of the tube; measurement on the opposite tubing wall is not possible without adding more sensors. Laser systems are combined with the ultrasound thickness results to provide complete dimensional measurements.

Luna’s time-domain terahertz sensor can make very fast and high-precision measurements of these parameters with a single non-contact reflection sensor unit. The measurement concept is like ultrasound while operating in air. This is particularly important in situations where the water bath associated with ultrasound measurement devices cannot be used.

A Terahertz (THz) sensor emits a very narrow, completely safe, low-energy pulse, which travels through air. Therefore, the probe is non-contact and operates with long standoff distances (25 mm, 75 mm or 150 mm).

The emitted THz pulse will reflect off interfaces in the sample, such as the air/outer wall and the internal interfaces between materials in a multilayer wall. The Time-of-Flight (ToF) between the reflections is measured, and the layer thicknesses are calculated from these values. Measurements are collected at a rate of up to 1000 Hz. The THz beam spot size is approximately 2 mm. Measurement precision as high as ±0.5 micron has been obtained.

Luna’s dual channel measurement system, when combined with our dual-beam sensors can measure four to eight points around the circumference of the tubing with zero moving parts. Measuring four or eight points around a tube with a single THz system, tube parameters such as ID, OD, wall thickness and concentricity can be measured simultaneously.

To learn more about a better on-line measuring and control solution, read our Tubing THz Applications Note.