Live, In-Vehicle Strain Monitoring Provides HD Data on Performance of Lightweight Materials

The automotive industry is working towards more sustainable vehicles and lower carbon footprints. One of the ways to achieve this is by decreasing the weight of vehicle components by using composites and other lightweight materials.

Compared to commonly used metals, these futuristic materials can be more difficult to model due to more complex failure mechanics and manufacturing processes. High-density strain data can help validate models, and High Definition Fiber Optic Sensing (HD-FOS) is a tool that can provide the density of measurements required for model validation for new materials.

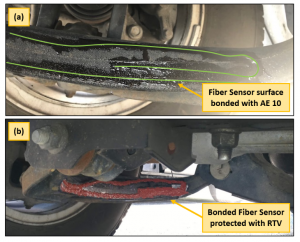

It is also important to gain a greater understanding of how these new materials behave under loading when integrated into a full design. A team of Luna engineers tested the versatility of the ODiSI 6000 System and its ability to make high-resolution measurements even in dynamic, real-world conditions.

They instrumented a vehicle with the ODiSI system and drove while taking HD-FOS measurements in highway and gravel road conditions. The team found that HD-FOS measurements were very stable for the highway data, and turning and breaking events were distinguishable when they occurred. While driving along the gravel road and over deep pot holes, the measurements became noisier at higher vehicle speeds but always recovered. Despite the high vibration, the sensors and the system saw no damage or failures in operation.

This capability and dependability allows for analysis of new materials and components or structural health monitoring in and outside the lab to ensure that new, lightweight parts meet needed design specifications.