Using Luna's ODiSI Fiber Optic System to Monitor Roadway and Structure Repairs

The durability of concrete structures diminishes over time due to several factors, such as environmental weathering, thermal cycling, fatigue, and chemical attack, requiring periodic inspection and repair. In civil structures such as roads and bridges, repair of surface damage needs to be carried out with materials and methods that are rapid setting, have high compressive strength, and exhibit long lasting durability under severe environmental conditions.

Luna’s high-definition distributed fiber optic sensing technology was recently used in the evaluation of a new rapid setting, cure-on-demand polymer resin system for roadway and structural repair. The new polymer-based repair material is of interest for enhanced chemical resistance, long working life, and fast setting time. These attributes could enable a rapid repair method for structures such as roadways and airfields where minimizing traffic closures is critical.

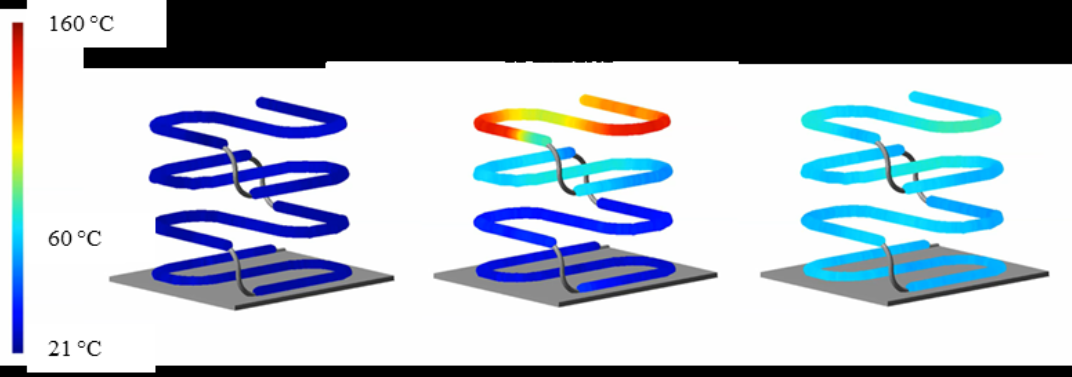

The characterization of the curing process was performed on a prototype patch that was prepared, incorporating optical fiber sensors into the epoxy-based specimen. The sensor configuration allowed researchers to monitor heat flow through the thickness when heated top-down using an infrared heater to start the reaction. Luna’s Optical Distributed Sensing Interrogator (ODiSI) was used to measure temperature at points located every 0.65mm along the length of a 2-meter fiber optic sensor at a rate of 60 Hz. The sensor was placed into the prototype patch as it was being poured and provided a temperature profile of the exotherm through the full thickness of the patch to ensure a full cure.

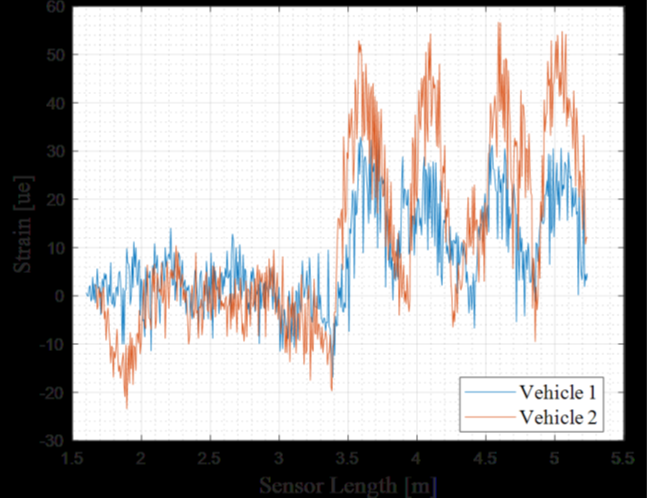

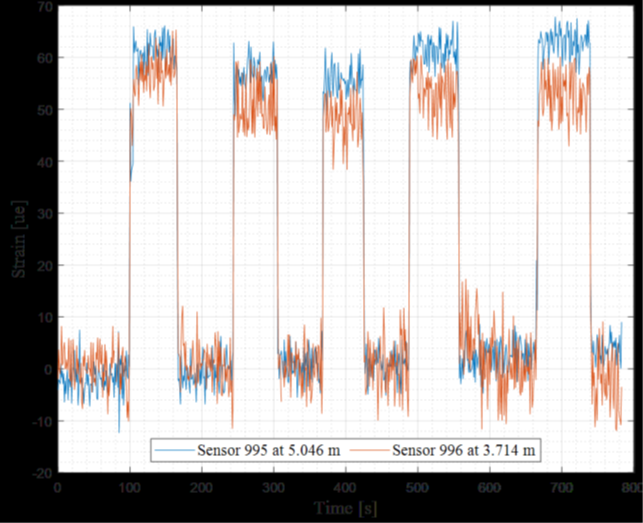

One advantage of using this technology to monitor the curing process was that it remained in the sample and enabled fatigue monitoring during structural testing. The ODiSI 6000 series instrument was used to monitor the epoxy concrete specimen under various loading conditions. During initial testing, vehicles of differing gross weights were both parked on the specimen for extended periods as well as driven on and off the specimen. The figures below show the strain measured by the sensor for both vehicles as a function of sensor length as well as time series data from two points along the fiber during one loading cycle.

With the increasing deterioration of civil infrastructure around the world, rapid setting epoxy concrete resins offer an attractive emerging technology for maintaining roadways, bridges, and commercial buildings. The use of high-definition fiber optic monitoring is enabling key measurements for physical attributes such as strain and temperature to quantify cure temperature profiles, strain responses to different vehicle load classes and even fatigue life characterization. The ODiSI solution is ideal because the optical fiber sensor is very small, lightweight, flexible, electrically passive and offers continuous measurements with gage lengths as small as 0.65mm. This technique measures the shift in the Rayleigh Backscatter pattern using Optical Frequency Domain Reflectometry (OFDR). To learn more about ODiSI high-definition distributed fiber optic sensing, please visit: https://www.lunainc.com/product/odisi-6000-series

Luna Innovations is enabling the future with fiber.

Reference:

Davis, M., Farnsworth, T.W., Williams A., Smith E., Brand A.S., Painter, T.T., “Fiber Optic Monitoring of a new rapid-setting, cure-on-demand polymer resin for roadway and structure repair”. Society for the Advancement of Materials and Process Engineering – North America, Proceedings of Virtual Event June 29 – July 1, 2021.