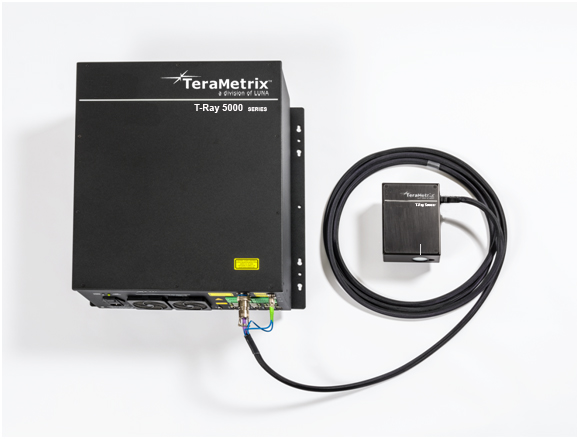

Product Spotlight: T-Ray® 5000 Terahertz Control Unit

The T-Ray® 5000 Intelligent Terahertz Control Unit (TCU) is the heart of the T-Gauge® Sensor Configuration. The TCU comprises the short pulse laser, time delay rails, data collection electronics and powerful calculation engine. With a waveform acquisition time of 10ms or 1ms, depending on configuration, the intelligent TCU is the fastest, full-featured time domain terahertz controller available.

Appropriate for use in both industrial and scientific applications the TCU monitors and controls all aspects of THz generation and detection. It delivers precisely controlled optical signals to the terahertz transmitters and receivers, or the T-Gauge® Sensor Heads, enabling them to generate and receive terahertz signals. Measured data are processed within the Control Unit at a rate of up to 1 KHz, making the T-Ray® 5000 one of the fastest terahertz systems available.

The data generated by the T-Gauge® Sensor Heads and processed by the T-Ray® 5000 Control Unit enable multiple measurements of a product simultaneously. One T-Gauge® Sensor can measure the basis weight, caliper thickness, multi-layer thicknesses, and density of a sample in a single pass.

Attached to a separate transmitter and receiver, the T-Ray® 5000 Control Unit can perform spectroscopic measurements as well as transmission and reflection imaging.

The T-Ray® 5000 Control Unit and accessories are linked with robust connection points and interfaces appropriate for industrial environments. Adequate connections are available to allow seamless integration with most QC systems or experimental applications. The industry-standard interface connections make integration with the T-Gauge® Sensor straightforward.

There are currently 4 variations to the TCU, each having different high-speed delays (HSD), which determine waveform lengths and speeds. Making the decision on which TCU configuration best suits your needs can be based on the following factors:

- Thickness of the sample: The reflection from both surfaces must be in the time window

- Required measurement rate: If high-speed measurements are required it may be necessary to use a 1000 Hz system

- Waveform averaging: For some difficult measurements it helps to average a few measurements together to improve bandwidth (waveform averaging) or precision (measurement averaging). This may require a 1000 Hz system so that even with averaging a measurement rate of at least 100 Hz will be maintained.

- Performance Tie Breakers: Best performance is always found with the shorter HSD time base at a given waveform acquisition rate for the TCU (i.e., 80ps of 1000 Hz and 320ps for 100Hz).

The TCU Model Number specifies the configuration of the HSD, the Industrial Interface, and whether the solid-state drive is internal or external. The model number is of the form TCU5xyz, where the options for x, y and z are listed below.

X specifies if the SSD is inside the TCU or if it is removable.

| X Options | |

| 2 | Internal SSD |

| 3 | External SSD |

Y specifies whether an industrial interface is present which includes an additional (shared) Ethernet port, 6 encoder inputs, 16 digital inputs, and 16 digital outputs.

| Y Options | |

| 1 | Industrial Interface |

| 2 | No Industrial Interface |

Z specifies the choice of high-speed delay.

| Z Options | |||

|

|

Length of delay (ps) |

Length of delay (reflection, mm) |

Rate of waveform acquisition (Hz) |

|

0 |

320 |

48 |

100 |

|

1 |

80 |

12 |

1000 |

|

2 |

160 |

24 |

1000 |

|

3 |

700 |

105 |

100 |

The length of the delay (mm) mentioned above is for propagation in air. Since light slows down as it travels through material, the maximum thickness of product that can be measured will be reduced by the index of refraction at THz frequencies. For foams this index can be as low as 1.1, while for ceramics it can be 3 or higher.

For more information on TeraMetrix measurement systems and which T-Ray® 5000 Terahertz Control Unit can help improve your manufacturing process please contact our team.