Luna coating provides radiation protection in space

The space environment poses significant challenges to technology platforms, space exploration, and mission assurance. Mission planners are continually striving to push technologies further to explore new and environmentally harsh regions of the universe. Highly charged environments can exist at Geosynchronous Earth Orbit (GEO), Medium Earth Orbit (MEO), and Polar Low Earth Orbit (PLEO) owing to solar winds/storms and charged particles trapped in Earth’s radiation belts.1-3 Just as there are numerous threats and sources of radiation in Earth’s orbit, deep space missions encounter radiation levels that can exceed the performance capabilities of current technology platforms. A possible future mission to explore Jupiter’s moon Europa, for example, would encounter radiation levels seven times greater than Earth’s orbit. There is a specific need for advanced materials to protect sensitive spacecraft electronics from harsh energetic conditions across a variety of different mission platforms. To serve this need, Luna has developed a charge dissipating conformal coating to enable greater radiation hardening and electrostatic discharge (ESD) mitigation for spacecraft electronics.

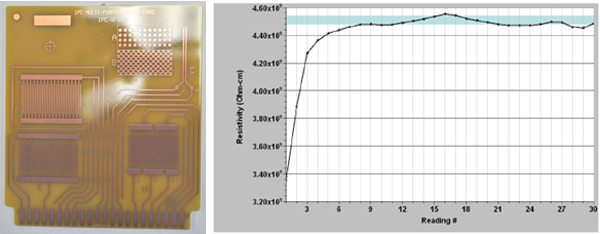

The developed coating (termed “LUNA XP-CD) meets the required volume resistivity of 1x108 – 1x1012 ohm-cm for ESD protection across a wide temperature range (see Figure 1), is optically transparent, inspectable under ultraviolet light, easy to apply and repair, provides low outgassing, and has excellent adhesion and flexibility. The coating offers performance properties of both common conformal coating protection and radiation hardening through ESD mitigation. The addition of ESD protection in a single conformal coating gives spacecraft designers a new tool to protect sensitive electronics from hazardous radiation environments, while simultaneously reducing spacecraft complexity, weight, and cost.

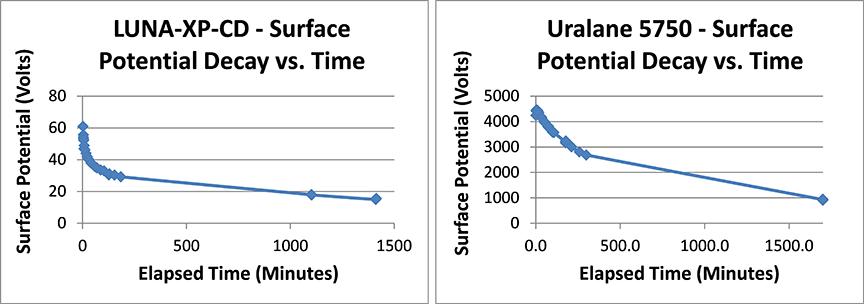

Charge dissipation testing was performed by the NASA Jet Propulsion Lab (JPL) using a custom electron gun test method that charges materials with up to 100 keV and then measures ESD events and surface potentials. Testing was also performed on a commercial polyurethane conformal coating often used for space missions (Uralane 5750) and compared to the Luna XP-CD coating. Potential decay plots as a function of time are shown in Figure 2 for each coating. The Luna XP-CD product provided a substantial reduction in retained charge at both early times (35V for Luna XP-CD vs. >4000V for the Uralane after ~1 hour) and later times (15V for Luna XP-CD vs. ~1000V for the Uralane after 24 hours or 1440 minutes).

Luna has partnered with NASA Langley Research Center to evaluate the charge dissipating coating on the upcoming Shields-1 CubeSat mission.4 A CubeSat is a miniaturized satellite that enables cost-efficient research on space technology. The mission will serve as a test bed for a variety of radiation protective materials. A successful mission will pave the way for future programs to utilize the Luna coating for electronics protection during GEO, MEO, Polar LEO and Outer Planets exploratory missions.

The coating was developed through a NASA STTR project under Contract #NNX11C129P.5 For more information on Luna’s XP-CD charge dissipating coating, please contact Adam Goff at 434-220-2513 or [email protected].

- Stassinopoulos, E. G. & Raymond, J. P. The space radiation environment for electronics. IEEE 76, 1423–1442 (1988).

- Johnston, A. H. Radiation effects in advanced microelectronics technologies. IEEE Trans. Nucl. Sci. 45, 1339–1354 (1998).

- Zeynali, O., Masti, D. & Gandomkar, S. Shielding protection of electronic circuits against radiation effects of space high energy particles. Appl. Sci. Res. 3, 446–451 (2012).

- https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20160006374.pdf

- Charge Dissipating Transparent Conformal Coatings for Spacecraft Electronics (NASA Phase I SBIR, Contract# NNX11CI29P).