Improve Process Temperature Monitoring in Thermoplastic Welding

Embed Fiber Optic Sensors for In-situ Temperature Measurements at the Weld Zone

An important innovation in the ongoing adoption of lightweight materials is the use of induction welding to join composite materials based on a thermoplastic polymer. With this process, an induction coil creates eddy currents within two composite parts. The process heats the polymer to the point of melting. The two parts are pressed together, forming a strong and cohesive bond that removes the need for expensive and heavy fasteners, such as rivets or bolts.

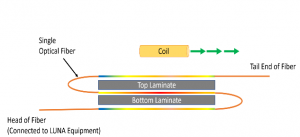

Due to the natural variances of the materials, monitoring the internal temperature of the weld is needed to guarantee a successful and robust weld. Unfortunately, IR cameras only see the surface temperature, and thermocouples are too bulky for embedding in the material. Fiber optic sensors, on the other hand, can be embedded along the weld line to provide real-time temperature monitoring during the induction weld.

This solution is the subject of a technical paper presentation at the Automotive Composites Conference and Exhibition (ACCE) September 7 in Novi, Michigan. Luna will be presenting “In-Process Monitoring of Induction Welding of Thermoplastic Composites Based on Fiber Optics,” authored with the University of South Carolina and Zeus Industrial Products. The presentation will describe how optical fiber can provide valuable in-situ temperature measurements at the weld zone. The research also explored the use of an alternative coating of the fiber sensor that would essentially melt off, further reducing the size of the embedded sensor.

This solution is the subject of a technical paper presentation at the Automotive Composites Conference and Exhibition (ACCE) September 7 in Novi, Michigan. Luna will be presenting “In-Process Monitoring of Induction Welding of Thermoplastic Composites Based on Fiber Optics,” authored with the University of South Carolina and Zeus Industrial Products. The presentation will describe how optical fiber can provide valuable in-situ temperature measurements at the weld zone. The research also explored the use of an alternative coating of the fiber sensor that would essentially melt off, further reducing the size of the embedded sensor.