High-Definition FOS Delivers the Detail for Bridge Structures

The role of structural health monitoring (SHM) in the effective management and maintenance of our aging infrastructure continues to grow and evolve. The success of any SHM program will hinge on the ability to accurately measure and monitor key parameters. Particularly in concrete structures, such as bridges, the detection, localization and monitoring of small cracks is critical.

Currently, crack detection and monitoring on bridges rely heavily on visual inspection or sometimes point sensors for strain or displacement. However, these methods have obvious limitations, including an inability to detect cracks that are subsurface or that occur in the spaces in between point sensors.

On the other hand, the ODiSI system with high-definition, distributed fiber optic sensing (HD-FOS) can directly detect cracks and micro-cracks continuously along the entire sensing fiber path. And the ability to embed rugged, but thin, optical fiber sensors into the structure extends crack detection to areas not reachable with traditional methods. To further facilitate these applications, SHM System has developed Nerve-Sensors, ruggedized, composite distributed strain sensors that feature a monolithic construction with no intermediate layers separating the optical fiber from the monitored object. This ensures the optimal transfer of strain to the fiber, which is essential for measurement accuracy and precision.

By combining Luna’s ODiSI high-definition optical interrogator with Nerve-Sensors (Figure 1) embedded into the reinforced concrete slab of steel-concrete bridges, engineers can accurately detect cracks, monitor crack growth and capture the general structural performance of the bridge deck under load.

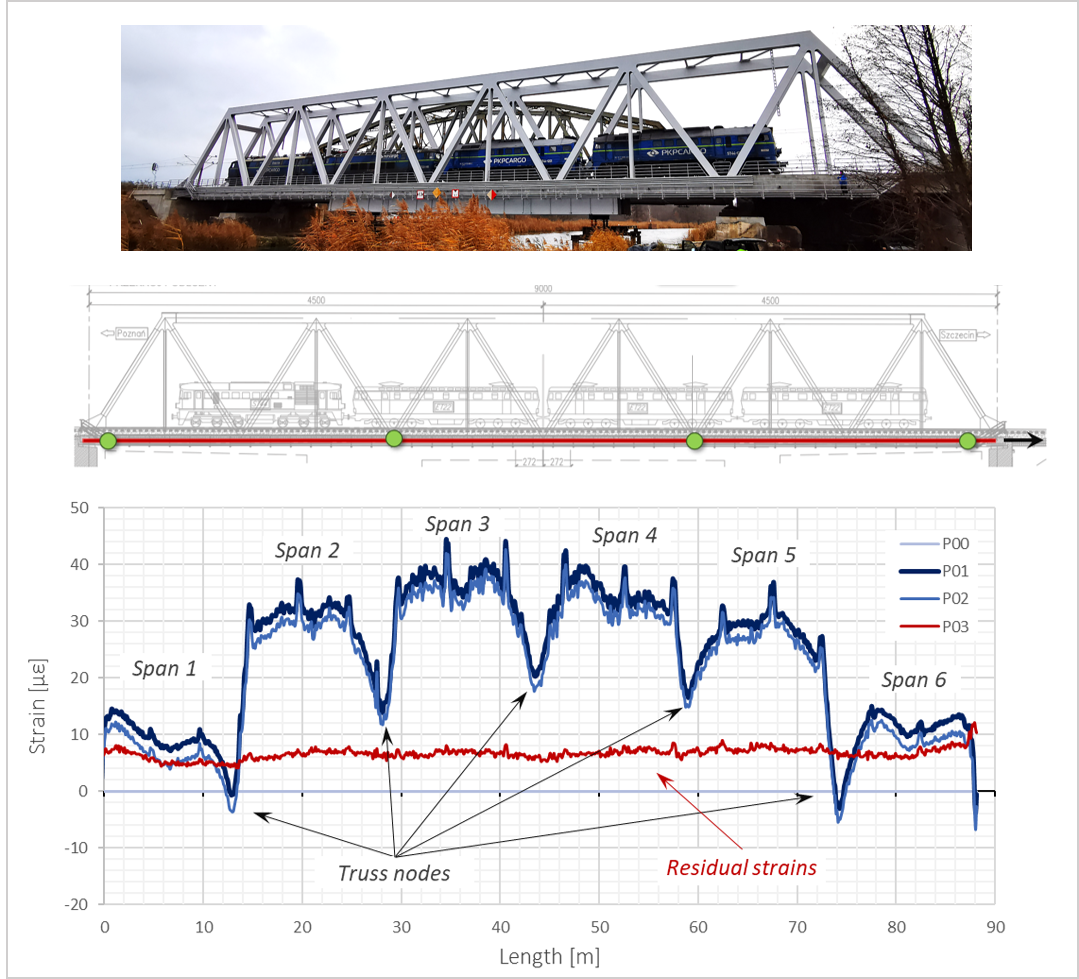

The image to the left shows an example of the strain profile from a steel truss bridge crossing the Noteć River in Poland that was instrumented with high-definition Nerve-Sensors embedded in the deck along its entire length. The resulting high-resolution strain profile accurately corresponds to the geometry of the truss superstructure.

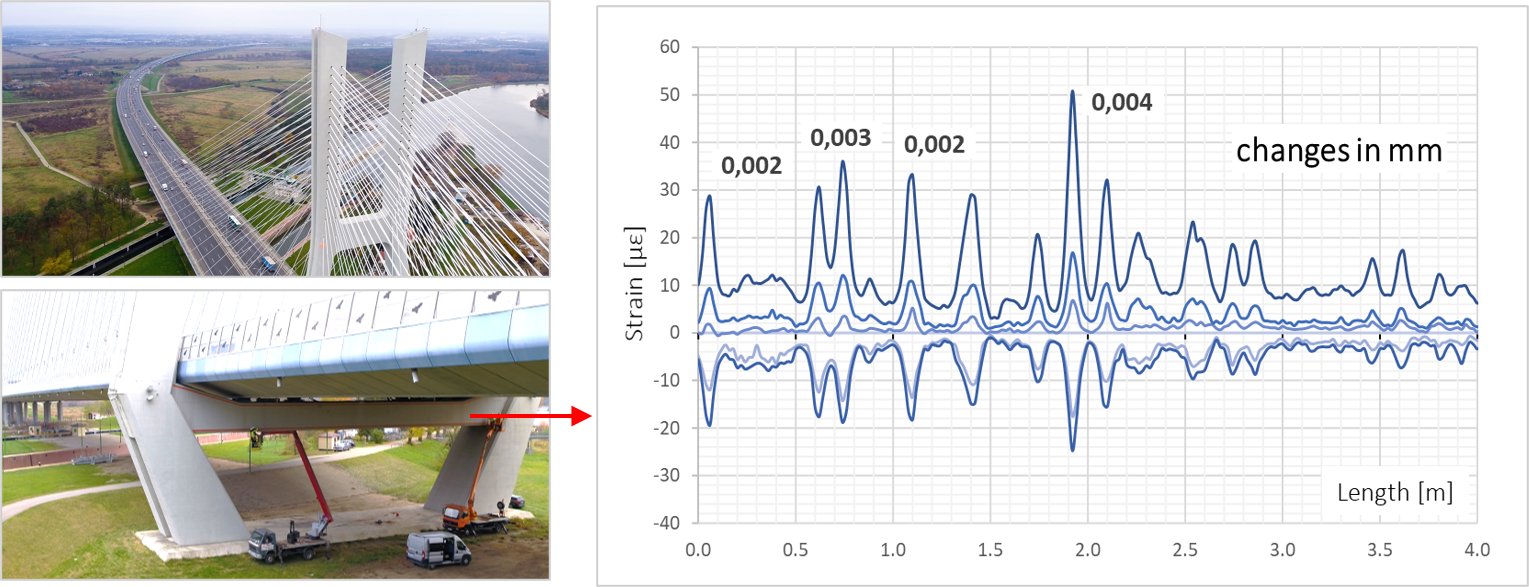

The ability of HD-FOS and the Nerve-Sensors to detect small cracks is illustrated on a large prestressed concrete bridge in Wroclaw, Poland, pictured below. The rugged composite sensors were integrated into the large bridge pylon for a detailed analysis of crack patterns along the supporting beam. Despite the very small size of the cracks, changes in crack widths under traffic loads were able to be captured in real-time and analyzed.

Similarly, Luna’s HD-FOS technology and Nerve-Sensors have been deployed in a wide range of civil and geotechnical structures, including deep foundations, piles, roadways, buildings, etc.

For more information on the ODiSI and its capabilities for very high definition distributed sensing, click here.

For more information on the Nerve-Sensors heavy-duty strain sensors designed for civil and geotechnical applications, click here.