SpaceX Lifts Luna to the International Space Station

On May 4th, 2018, the SpaceX Dragon capsule will return to Earth after spending a month at the International Space Station (ISS). The Dragon capsule arrived to the ISS on April 4th when it delivered more than three tons of goods including food, supplies, and research materials from Luna Innovations. Luna’s technology development division (Luna Labs) has been awarded several contracts for new materials development in support of critical NASA missions. Three of these developmental space materials were onboard the Dragon cargo carrier and are among many other research materials mounted to NASA’s new Materials International Space Station Experiment (MISSE-9) flight facility. The MISSE-9 will be installed on the exterior of the ISS rotating laboratory. After prolonged exposure to outer space, Luna’s samples will be returned to Earth for performance evaluations, advancing Luna’s evaluation of how these materials will perform for NASA.

SpaceX Falcon rocket launches the Dragon cargo carrier and MISSE-9 facility on April 2 2018 at Cape Canaveral Air Force Station, FL.

About the MISSE-9 Flight Facility

For the Dragon space capsule, this trip was a repeat of a 2016 trip to the ISS. However, this is the first trip for the new MISSE-9 developed by Alpha Space Test and Research Alliance of Houston. The flight facility will be permanently mounted to the outside of the ISS, exposing components, materials and coatings to the harsh conditions of outer space. Experiments requiring long exposure to outer space can remain in place on the facility for years if desired. This provides NASA researchers and commercial organizations with a unique opportunity study the effects of outer space on material samples. Prinicpal investigators of the MISSE-9 are Alpha Space Test and Research Alliance’s Stephanie Murphy and Mark Gittleman. Click here to learn more about the NASA’s MISSE-9 flight facility.

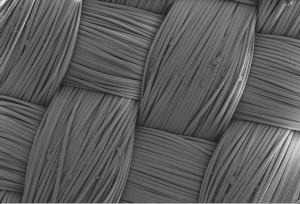

500 Days on Mars: Luna’s New Spacesuit Materials

NASA is planning for future manned missions to Mars that will require extended human protection for up to 500 days. In support of such missions, there is a need to develop improved textiles for Environmental Protection Garments (EPG) that are specifically designed to protect against long-term environmental exposure. Critical capabilities for these textiles include improved i) dust mitigation to protect from potentially corrosive or abrasive particles in the Martian regolith, ii) cut and puncture resistance to protect the suit bladder from damage from sharp edges of tools and rocks, and iii) durability for extended use.

Luna responded to this need with the development of a multifunctional composite textile system that will achieve these stringent goals, while providing improved comfort and mobility. This practical textile design provides excellent protection from many hazards including dust, fire, cut, puncture, as well as chemical, thermal and environmental exposure. The developmental textile is intended for use in environmentally protective spacesuits, specifically for the Mars missions. This spacesuit textile material is currently mounted onto the MISSE-9 at the ISS due to its direct relevance to Extravehicular Activity (EVA) suits currently employed by NASA for spacewalks on the ISS.

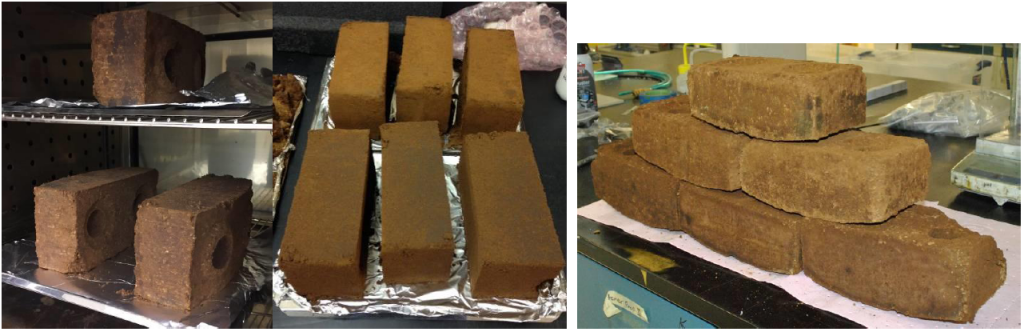

Using Space-Based Resources for Human Missions in Deep Space

Expanding the capability of human exploration is a primary goal for NASA’s In-Situ Resource Utilization (ISRU) program, which focuses on transforming available material resources on extraterrestrial surfaces into usable materials and products. By identifying, collecting, and converting local resources into products that can reduce mission mass, cost, and risk, a sustainable manned expedition to Mars becomes closer to reality. To meet the needs of NASA’s ISRU program, researchers at Luna have identified a polymer concrete formulation based on urea-formaldehyde (UF) binder that can be pressed into high compressive strength interlocking bricks suitable for construction on Mars. Luna’s binder system can be produced in-situ from feed gases identified by NASA (N2, H2, CO2), while concurrently generating O2 and water. Luna successfully demonstrated utilizing UF resin and Mars regolith simulant to produce interlocking bricks. The UF polymer concrete formulations were tested and found to have good compressive strength, excellent freeze/thaw resistance, and good flame resistance. A sample of Luna’s UF polymer concrete is currently mounted on the MISSE-9 for exposure to outer space. The data obtained from the ISS would be useful to determine the effect of radiation exposure has on these materials.

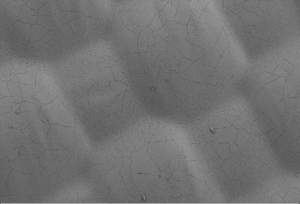

Thermal Protection System (TPS) for Orion Spacecraft

NASA’s Orion spacecraft is an exploration vehicle that will carry a crew to space, provide emergency abort capability, sustain the crew during the space travel, and provide safe re-entry from deep space return velocities. Planetary Aerocapture and entry requires that the crew vehicle be equipped with a Thermal Protection System (TPS) comprised of lightweight, high performance ablator materials. There is a need for advancements in polymers for use in bonding and/or gap fills for tiles of advanced TPS for extreme entry conditions.

To meet this need, Luna leveraged its expertise in both polymer chemistry and adhesive/sealant formulation to develop a flexible gap fill material which outperforms existing sealants for most physical and thermal characteristics relevant to extreme requirements of TPS. The binder for the gap fill is a flexible, low glass transition temperature polymer with a high decomposition temperature/char yield (comparable to phenolic) and a high (>1%) strain-to-failure that is compatible with cured epoxy, phenolic, and/or cyanate ester. Luna utilized a novel urethane copolymer elastomer with a very low glass transition (< -70°C). This resin can be highly filled to tune ablative properties and is compatible with glass and carbon fabric substrates. Luna’s flexible gap filler for ablative thermal protection systems is one of the three Luna materials mounted onboard the MISSE-9 at the ISS.

For more information about Luna’s developmental space materials reach us at [email protected].