Cracking, Corrosion, and Carbon Nanotubes – Come See How We’re Working with Each! (Part 2)

Jeff Demo Electrical Systems Team Lead Intelligent Systems Group In our last post, we let you know about the early March conference activities we had on our calendar. Coming up in mid-march, we have the NACE International Corrosion 2015 Conference & Expo with three additional paper presentations. Conrad Andrews, Mara Schindelholz, and Robert Jeffers will each have a presentation at the NACE Corrosion Conference about their respective work in the fields of corrosion and cracking. Conrad will discuss Luna’s coating condition monitoring system, Mara will talk about stress corrosion cracking (SCC) in aluminum, and Robert will present his work with corrosion-resistant, carbon nanotube primers. Also, don’t forget to stop by our exhibit booth at Corrosion 2015 – we’ll be in booth #14008 with demonstrations of our corrosion sensing and crack detection systems along with literature on many of Luna’s cutting edge technologies. Details for each presentation are below; we hope to see you there! Low-Cost Autonomous Condition Monitoring System for Tank Coatings Conference: NACE International Corrosion 2015 Conference & Expo, Dallas, TX Presenter: Conrad Andrews ([email protected]) Date, Time, Location: March 16, 1:50PM. Room 163, Kay Bailey Hutchinson Convention Center

Navy ships rely on a combination of coatings and cathodic protection systems to protect steel tanks and enclosures. Corrosion of tanks and enclosures was named the top corrosion expense on Navy vessels, and recently accounted for $250 million in annual direct costs. To combat this issue, Luna is developing a coating condition monitoring system that measures environmental conditions and electrochemical parameters for evaluation coating, substrate, and cathodic protection systems health. In his talk, Conrad will review previous performance demonstration results using two-dimensional steel plates as well as the extension of the system to three-dimensional structures representative of ballast water tanks. The presentation of this work, supported by an ongoing Phase II SBIR program, will give an overview of coating health modeling, the use of artificial neural networks for damage state modeling, and the successful results obtained when testing in three dimensions. Small Scale Crack Growth Sensor for Determination of AA5XXX Susceptibility to SCC Conference: NACE International Corrosion 2015 Conference & Expo, Dallas, TX Presenter: Mara Schindelholz ([email protected]) Date, Time, Location: March 16, 2:25PM. Room 173, Kay Bailey Hutchinson Convention Center

Stress corrosion cracking (SCC) of AA5XXX exposed to the atmosphere is a critical safety issue for DoD assets, often resulting in service failures. To more accurately assess AA5XXX susceptibility to SCC, a standalone in situ crack growth sensor has been developed to monitor crack propagation within a surrogate tensile sample under realistic atmospheric conditions. Using tailored test specimens and exacting methods for loading, corrosive conditions and load interaction effects on SCC can be evaluated in accelerated tests and outdoor environments. These measurements can then be used to identify the significant relationships between environmental parameters and SCC failure processes. In her presentation, Mara will provide an in depth look at the Luna’s SCC sensing system, crack propagation under various standardized accelerated corrosion tests, and the effect of cyclic relative humidity conditions on aluminum crack grown rates. Non-Chrome Corrosion-Resistant Primers with Carbon Nanotubes for Improved Performance Conference: NACE International Corrosion 2015 Conference & Expo, Dallas, TX Presenter: Robert Jeffers ([email protected]) Date, Time, Location: March 19, 9:25AM. Room 173, Kay Bailey Hutchinson Convention Center

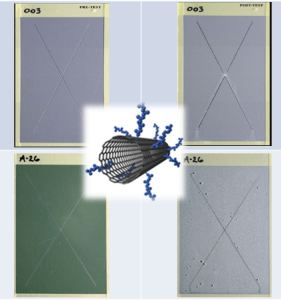

In the coating stack applied to military aircraft, hexavalent chromated primers are often used to protect the underlying aluminum structure from corrosion. However, heightened concern over toxicity has led to increased regulation of hex-chrome use and to petitions for their complete replacement with chrome-free inhibitors. Carbon nanotubes are of prominent interest due to their unique physical properties and potential to enhance the corrosion resistance of coatings through increased barrier protection and mechanical strength. In combination with common corrosion inhibitors they can provide synergistic effects enhancing corrosion resistance. Luna has been developing an innovative chrome-free corrosion resistance primer based on the incorporation of carbon nanotubes. The primer has demonstrated excellent corrosion resistance in both neutral and acidified salt fog testing. Come learn more about the coatings as Robert presents details related to the development and evaluation of the new coatings along with the promising laboratory test results indicating improved performance over legacy chrome coatings.